So, today I’m gonna show you how I use my CNC for more then making it.

First we need a motif.

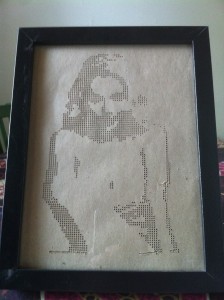

I searched the internets for a picture of something pretty or cool, then I stumbled upon this image of Scarlett Johansson.

Then you need to pre-process it a bit, I removed all the things that where not Scarlet, then used the threshold function go get it black and white and finally I cut it out all the white that I didnt really need.

Cutting out that stuff also makes it easier to align and size up whatever I’m going to drill in. Now it’s time to use a processing script I originally wrote to generate svg-codes. It now generates gcodes (aswell as an image). One thing to remember is that you need to be careful of whatever size you’re drillbit is, it’s easy to get exited and start to soon. A bit of calm thinking and checking the spacing between the holes is needed.

fx: between Y6.0, X44.4 and Y6.0, X45.6 is 1.2mm difference. that is fine if you have like, half a mm sized drillbit. I don’t want that small so I’m tweaking the processing script. This particular time it came down to 2878 holes.

This is how the preview looks:

Right now the CNC is drilling holes in a piece of paper that I’m gonna put into a frame I bought at IKEA. I’ve noticed that It sometimes get’s a bit stupid and tries to take the shortest way to a point that I have not told it to go to. Guess I have to remake more of the source, or perhaps rewrite it. I never use the circle part anyway’s. perhaps a bezier addition could be nice? anyway’s here is a little video of the machine drilling away, not very interesting to watch.

Of course I managed to move the paper around when I should not, crap. And I’ve noticed that the spindle sometimes takes the closes way to a point I haven’t even specified. Guess I have to take a look at that arduino code again. But I’ll wait until I get a laser up and running!

As you can see from this final photo I had to stop it since it started to tear things apart. I really got to fix that bug. So I wont put light’s behind either. I’ll probably throw it away soon. But still It’s good to document things once in a while!

Finally here’s the processing source: CNC_Director

Pingback: idle hands › CNC plotter style

Coolness!!

I actually thought that the paper would rip apart when drilled, but nice to see it working.

So when will you start up your business for CNC services? 😉

//P

Dunno if I have a real bisniss-case here 🙂

the drill is moving at 30 000 rpm, so it’s pretty fast!